The XMT9007-8 temperature & humidity instrument is an intelligence instrument based on the computer technique. It adopts a 2-row digital 8 high-light 7 sect LED and synchronous display both the humidity and drying temperature measured. The control parameters can be set by panel and displayed in real-time.

The user can choose below functions

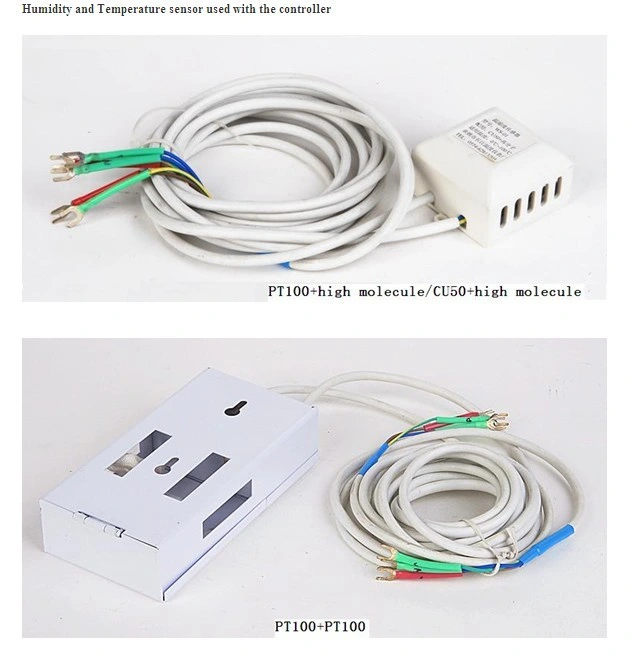

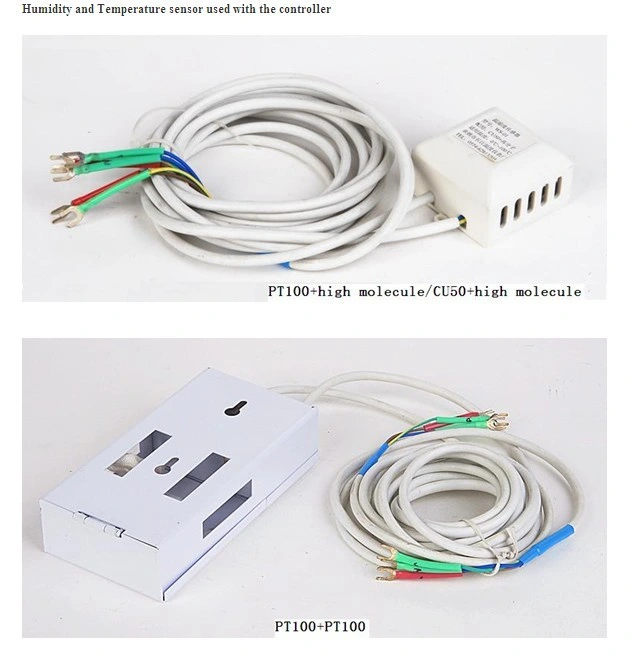

1. Sensor: PT100 sensor for temperature measurement, PT100 OR high molecular sensor for the humidity measurement.

2. Control mode: PID and on/off mode for heat and humidity control. On/off mode for cool control. On/off control is convenient for using; PID control can improve the meter control precision.

3. Serial communication: The computer can make a long-distance control to the meter by RS485 serial module.

4. Print function: The meter can regularly print annals and sample value of temperature and humidity by connecting mini printer.

Main Technical Specifications

1. Accuracy: Temperature measurement accuracy +0.5%F. S+1.0character Humidity measurement accuracy + 0.2%F. S+1.0 character

2. Temperature measurement range: -50.0-150.0C

3. Output relay: AC220V 10A

4. Power-off data-retention time: Over 10 years

5. Work Power: AC220V± 10% 50Hz Power consumption less than 5W

6. Normal working ambience: Temperature: 0-50C, Relative humidity: 35%-85% without corrosive gas-free space

7. Power on, in case"-----"or "----", or "100% humidity" is always displayed in both the upper and lower row windows respectively, please, check if the wire of the sensor is broken, or if a case of short circuit or other problem, such as wrong connection, etc.

8. External dimension and Installation hole(mm): 160× 80× 125 Installation hole 152× 76

Sense of Model Code

X M T(-) -9007-8 (-)

1 2

1: the exterior size (mm):

None: 160*80*120 hole: 152*76

"A": 96*96*110 hole: 92*92

"D": 72*72*110 hole: 68*68

"F": 48*96*110 hole:44*92

2: suffix

None: relay on-off output

"WT": with mini printer output function

"K" : with RS485 PC communication function

"C2": with electric current transfer output function

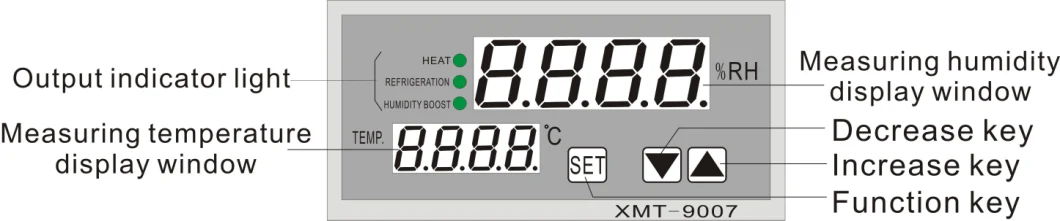

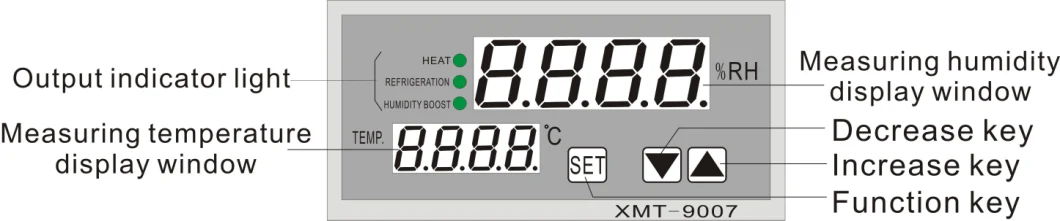

The panel specification(consult)

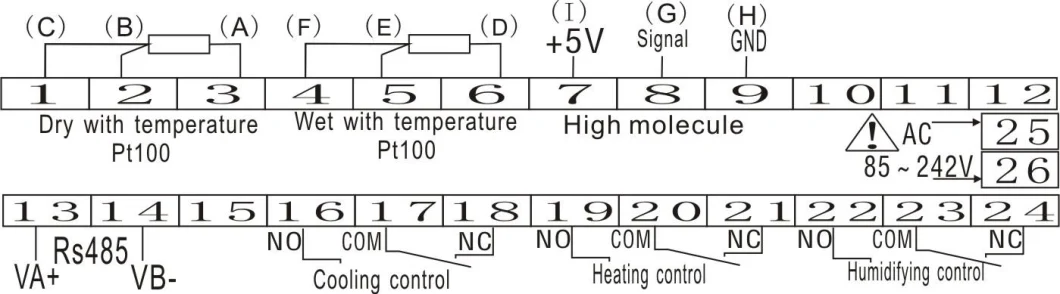

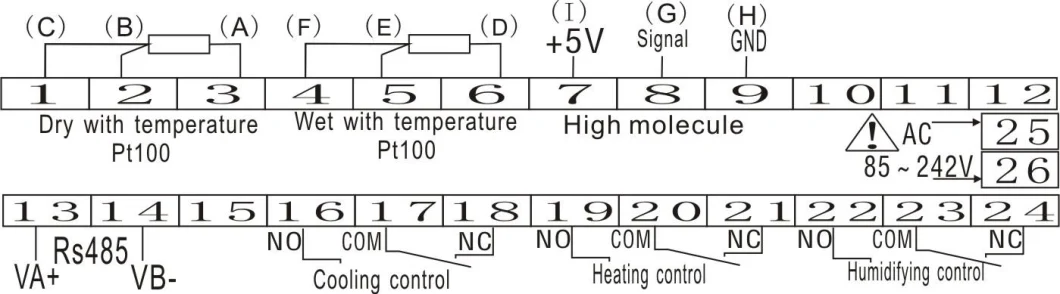

Connection scheme (consult)

The second menu:(Print parameters)

The user can choose below functions

1. Sensor: PT100 sensor for temperature measurement, PT100 OR high molecular sensor for the humidity measurement.

2. Control mode: PID and on/off mode for heat and humidity control. On/off mode for cool control. On/off control is convenient for using; PID control can improve the meter control precision.

3. Serial communication: The computer can make a long-distance control to the meter by RS485 serial module.

4. Print function: The meter can regularly print annals and sample value of temperature and humidity by connecting mini printer.

Main Technical Specifications

1. Accuracy: Temperature measurement accuracy +0.5%F. S+1.0character Humidity measurement accuracy + 0.2%F. S+1.0 character

2. Temperature measurement range: -50.0-150.0C

3. Output relay: AC220V 10A

4. Power-off data-retention time: Over 10 years

5. Work Power: AC220V± 10% 50Hz Power consumption less than 5W

6. Normal working ambience: Temperature: 0-50C, Relative humidity: 35%-85% without corrosive gas-free space

7. Power on, in case"-----"or "----", or "100% humidity" is always displayed in both the upper and lower row windows respectively, please, check if the wire of the sensor is broken, or if a case of short circuit or other problem, such as wrong connection, etc.

8. External dimension and Installation hole(mm): 160× 80× 125 Installation hole 152× 76

Sense of Model Code

X M T(-) -9007-8 (-)

1 2

1: the exterior size (mm):

None: 160*80*120 hole: 152*76

"A": 96*96*110 hole: 92*92

"D": 72*72*110 hole: 68*68

"F": 48*96*110 hole:44*92

2: suffix

None: relay on-off output

"WT": with mini printer output function

"K" : with RS485 PC communication function

"C2": with electric current transfer output function

The panel specification(consult)

Connection scheme (consult)

| Series | Code | Name | Setting range | Description | Ex-factory |

| 1 | LOCK | Password | 0~200 | Lock=0, can modify adjust all parameters except Sn parameter. Lock=155, Sn parameter only can be set. | 0 |

| 2 | C1 | Heating set value | -50.0~150.0 | Set the heating temperature value Please refer to "7.1\heating control" | 50.0 |

| 3 | RH | Humidifying set value | 0.0~100 | Set the humidifyingset value Please refer to "7.2\humidifying control" | 70.0 |

| 4 | C2 | Cooling set value | -50.0~150.0 | Set cooling temperature value Please refer to "7.3\cooling output" | 60.0 |

| 5 | OPB | Expansion function | 0~2 | 0: no; 1: communication function; 2: print function | 0 |

| 6 | BT | Communication baud | 1200\2400\4800\9600 | 9600 | |

| 7 | ADT | Communication address or print interval time | 0~100 0~9999 | Communication setting range:0~100 Print setting range:0~9999(minute) | 1 |

| 8 | tb | Cooling return difference | -20.0~20.0 | When the parameter is set to a negative number, that cooling have delayed function, delay time is three minutes. Please refer to "7.3\Cooling output" | 0.5 |

| 9 | P1 | Proportionality factor | 0~100.0 | Proportional band determines the size of the heating system proportional gain, P1 is greater, the proportion role is smaller, overshoot is smaller, but too small will increase the heating time. Set P1 = 0, heating turn to ON/OFF control status. | 15.0 |

| 10 | I1 | Integration time | 0~2000 | Set integration time to remove the residual error of the proportional control, and too great slow system achieving balance time, too small will produce fluctuations. | 240 |

| 11 | D1 | Differential time | 0~250 | Set the differential time, in order to prevent fluctuation of the output and improve the stability of the control. | 30 |

| 12 | T1 | Heating control cycle | 2~120 | The instrument is PID control, it is meaningful, it means the sum of closing time and opening time in the heating control output. | 10 |

| 13 | HY1 | Heating return difference | 0~50.0 | When the heating implement ON/OFF control, it is useful. Please refer to"7.1\Heating control". | 1.0 |

| 14 | AT1 | Heating setting itself | 0 or 1 | AT1 = 0, turn off the heating setting itself function; AT1 = 1, open the heating setting itself function. Please refer to instruction "VI\Setting itself " | 0 |

| 15 | P2 | Proportionality factor | 0~100.0 | Proportional band determines the size of the humidifying system proportional gain, P1 is greater, the proportion role is smaller, overshoot is smaller, but too small will increase the humidifying time. Set P1 = 0, humidifying turn to ON/OFF control status. | 15.0 |

| 16 | I2 | Integration time | 0~2000 | Set integration time to remove the residual error of the proportional control, and too great slow system achieving balance time, too small will produce fluctuations. | 240 |

| 17 | D2 | Differential time | 0~250 | Set the differential time, in order to prevent fluctuation of the output and improve the stability of the control. | 30 |

| 18 | T2 | Humidifying control cycle | 2~120 | The instrument is PID control, it is meaningful, it means the sum of closing time and opening time in the humidifying control output. | 10 |

| 19 | HY2 | Humidifying return difference | 0.0~20.0 | When the humidifying implement ON/OFF control, it is useful. Please refer to"7.2\Humidifying control". | 1.0 |

| 20 | AT2 | Humidifying setting itself | 0 or 1 | AT2 = 0, turn off the humidifying setting itself function; AT2 = 1, open the humidifying setting itself function. Please refer to instruction "VI\Setting itself " | 0 |

| 21 | Sn | Input type | 0 or 1 | 0:Equipped with PT100 + PT100 sensors; 1:Equipped with PT100 + high molecular sensors; | 1 |

| 22 | SC1 | Temperature sensor error revise | -20.0~20.0 | When between the measured temperature and actual temperature have error, you can amend by this parameter. | 0.0 |

| 23 | SC2 | Humidity sensor error revise | -20.0~20.0 | When between the measured humidity and actual humidity have error, you can amend by this parameter. | 0.0 |

| Series | Code | Name | Setting range | Description | Ex-factory |

| 24 | YER | Year | 0~99 | Set the year of printing time. | __ |

| 25 | YUE | Month | 1~12 | Set the month of printing time. | __ |

| 26 | DA | Day | 1~31 | Set the day of printing time. | __ |

| 27 | HO | Hour | 0~23 | Set the hour of printing time. | __ |

| 28 | FEN | Minute | 0~59 | Set the minute of printing time. | __ |